Predctive Maintanance

Predictive and Descriptive Maintenance offer several significant benefits for industrial operations:

Request a Demo

Predctive Maintanance enables you to

-Reduced Downtime and Unplanned Failures

Predictive Maintenance helps in identifying potential issues before they lead to equipment breakdowns. By addressing problems proactively, it minimizes unplanned downtime, ensuring continuous production and reducing costly emergency repairs

Optimized Maintenance Scheduling

Predictive Maintenance allows organizations to optimize maintenance schedules based on the actual condition of equipment. This means maintenance is performed when needed, rather than according to rigid, calendar-based schedules. It reduces unnecessary maintenance and maximizes the lifespan of assets

Cost Savings

Predictive and Descriptive Maintenance lead to significant cost savings. By reducing downtime, preventing catastrophic failures, and optimizing maintenance resources, companies can achieve substantial operational cost reductions

Improved Safety and Reliability

These maintenance approaches enhance the overall safety and reliability of industrial operations. By identifying and addressing potential hazards or issues early, they reduce the risk of accidents and equipment failures, contributing to a safer work environment and consistent product quality

How an Predctive Maintanance works for a factory:

1. Comprehensive Data Collection

Deploy IoT sensors and data collection devices on industrial machinery to gather a wide range of data, including temperature, vibration, pressure, and operational performance metrics

2. Real-time Data Processing

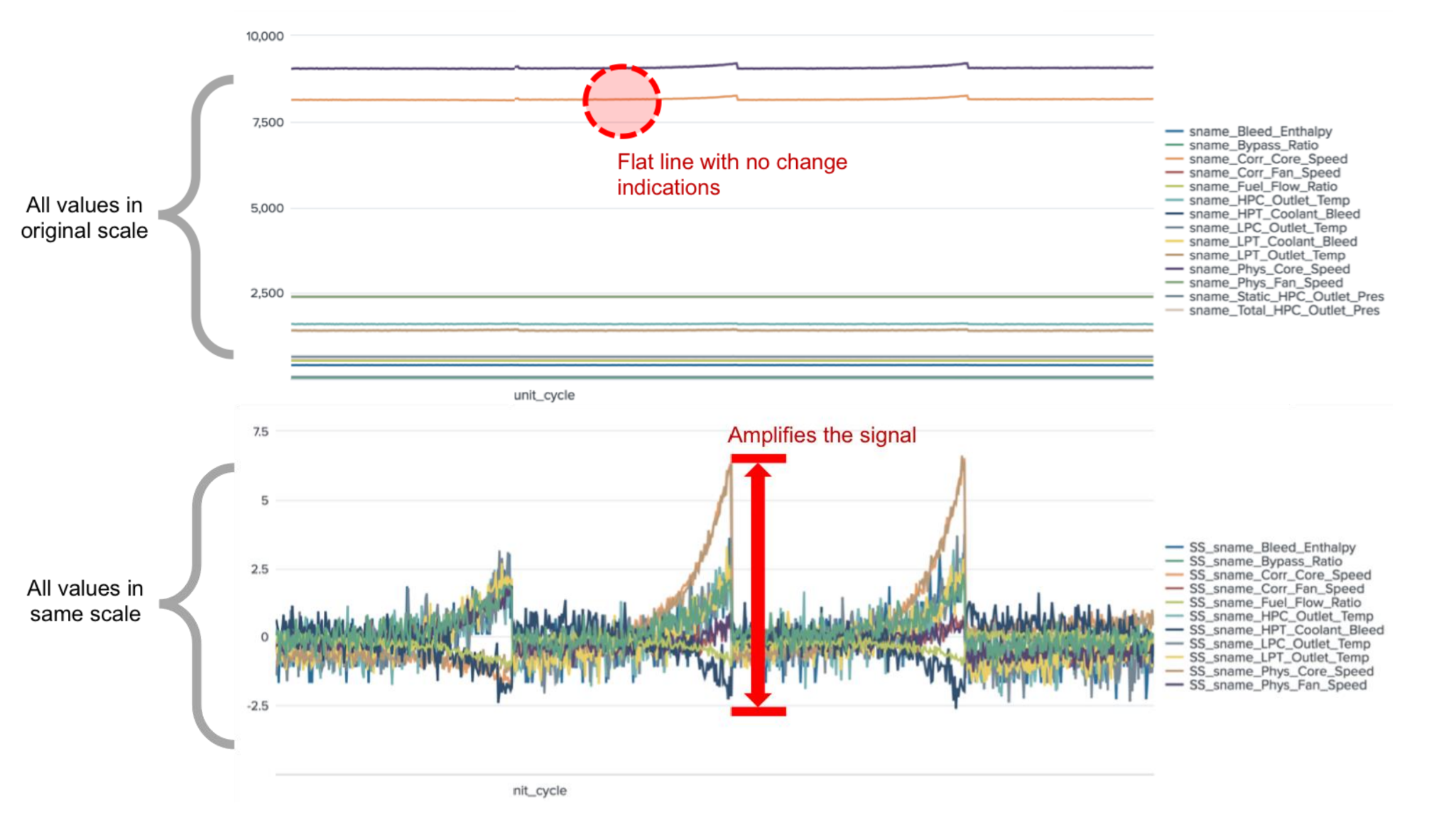

Utilize advanced AI algorithms to process and analyze the collected data in real-time. AI can detect anomalies and deviations from normal equipment operation with high precision

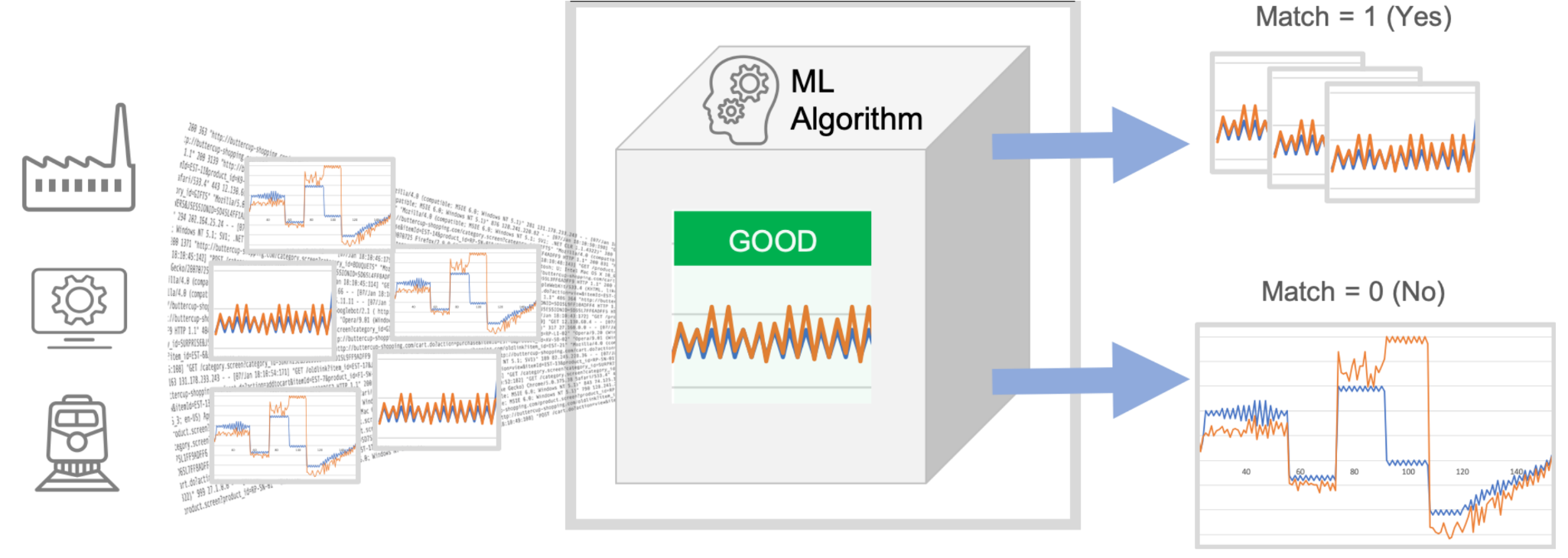

3. Predictive Maintenance Models

Develop robust predictive maintenance models based on historical data. These models predict when equipment failures or maintenance requirements are likely to occur, allowing for proactive scheduling

4 . Descriptive Maintenance Analytics

Harness descriptive maintenance analytics to gain insights into historical maintenance patterns. Analyze trends, root causes, and areas for improvement based on historical maintenance data

5. Downtime Minimization

Implement predictive maintenance recommendations to address potential issues well before they lead to downtime. This approach significantly reduces unplanned stoppages and production interruptions

6. Cost Optimization

Optimize maintenance schedules by considering the actual condition of equipment, reducing the need for expensive routine maintenance and extending asset lifespans

7. Safety Enhancement

Enhance workplace safety by addressing potential hazards early in the maintenance process. By preventing equipment failures, you reduce the risk of accidents and injuries

8. Continuous Improvement Cycle

Establish a systematic continuous improvement cycle that involves regular monitoring, data analysis, and fine-tuning of maintenance strategies. This ensures ongoing operational efficiency and safety

9. Resource Allocation Efficiency

Make smarter decisions about resource allocation for maintenance. Predictive and descriptive maintenance helps prioritize which assets need attention, streamlining the use of your maintenance workforce and materials